A unique solution to each new challenge

Our products come in all shapes and sizes, for a huge variety of settings and applications. Whatever you ask for, we’re confident we can make it, and that it’ll be the best in the industry, thanks to our specialist knowledge, and proven design and manufacturing processes.

We make our planters in galvanised steel, but can work in whatever material you wish, depending on the plant species, setting and overall effect required. For larger installations, we can work from simple sketches, an artist’s impression, full engineering drawings – or just an idea. In every case, we’ll use the latest design and drawing software to create a complete 3D, CGI model of your project, so you can see exactly what it will look like in situ.

However complex the brief, we’ll find a way to make it work. If people look at the finished piece and can’t work out how it was done (or believe it was even possible) then we’re happy.

We’re always ready for our next challenge. What can you give us to do?

-

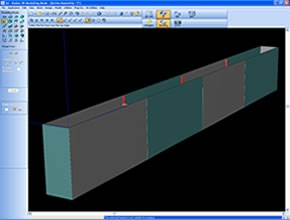

Design

Every planter design is conceived using the latest 3D Software ensuring all aspects can be proved and a full model supplied for client approval. Read more > -

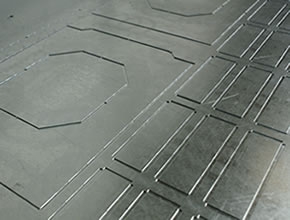

Punch

Manufacturing now starts with the punching of the planters individual parts, shapes and holes added and all based on the original 3D model. Read more > -

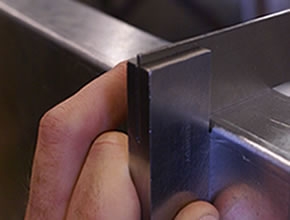

Fold

The individual parts start taking shape, details folded into the steel forming the ends, the base and lip details using the latest bending technology. Read more > -

Weld

The assembling of the individual components into a recognizable planter is carried out by our team of highly experienced welders. Read more > -

Polish

Once welded, the time consuming process of grinding and polishing begins ensuring the planter is both seamless and beautiful. Read more > -

Inspect

The fabrication process is now complete. Prior to painting, we carry out a thorough inspection to ensure the planter meets our high standards. Read more > -

Paint

The most gratifying part of the manufacturing process is the application of paint when the planters take on their own unique identity. Read more > -

Final Inspection

The planter is now finished but before it can be dispatched, we carry out a thorough final inspection looking for any flaws or defects. Read more >